The Centre of Excellence started with Refoil on the 25/06/2013

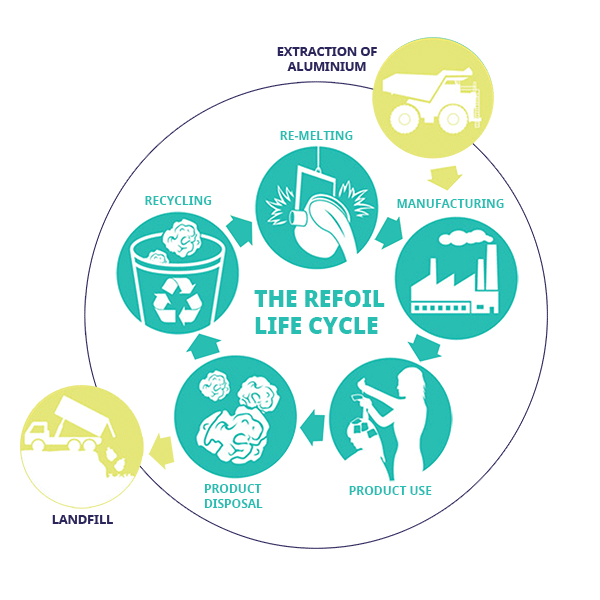

The Refoil life cycle:

Refoil, takes a lifecycle approach to making a sustainable decisions at every stage of their products’ life. They care for the environment at the heart of everything they do, from design, manufacture, and packaging right through to disposal.

Refoil is committed to make products mainly from recycled aluminium sources. By making their products from recycled aluminium they reduce the need for natural resources, divert waste from landfill and save heaps of energy and water (up to 95%) compared to the energy needed to mine, refine and smelt new aluminium.

Remelting

The starting point of their products is not the ground, but the aluminium remelting facility. That’s where the collected scrap aluminium is remelted into coils. Any leftover residue on the aluminium will be processed in a furnace where the coating will be removed. The remelting process requires only 5% of the energy and water used to produce aluminum from ore.

Manufacturing

In the manufacturing stage coils are rolled into sheets according to requested thicknesses. Rolling increases the strength of the aluminium and produces the foil’s two natural finishes, bright and matte. Finally the coils are cut and trimmed into Refoil’s customized sizes.

Product use

Colourists who care use Refoil as a colouring tool to highlight, weave and panel hair. Some colourists even use Refoil to enhance hair treatments by wrapping Refoil sheets around the client’s head. This technique captures heat and as a result makes the hair feel softer. Colourists who care always find new ways to use Refoil to suit their style.

Product disposal

Our friends at the recycling centre can’t process loose sheets of foil. They tear easily. Therefore it is important to crush the aluminium sheets into balls (Minimum the size of a tennis ball). The bigger the balls, the better! Dispose of the balls in the salon’s “Refoil only” bin. Not the waste bin!

Remember to give the aluminum sheets a light rinse before crushing though. This will make it easier for the recyclers to process. Any leftover residue on the aluminum balls will be processed in a furnace where the coating will be removed.

Recycling

Once your “Refoil only” bin is full, empty it in your mixed recycling wheelie bin (generally provided by local council). The local authorities transport the content of this mixed recycling bin to a Materials Recovery Facility (MRF) where the recyclables are sorted.

In the MRF the Refoil balls will be sorted from the other recyclables. The sorted Refoil balls are baled and send to a remelting facility for resource recovery purposes.

Benefits of recycling

- Water savings. Recycling saves up to 97% of the water used in refineries to process ore into alumina. Recycling one kilogram of aluminium saves approximately 233 litres of water.

- Energy savings. Smelting alumina into pure aluminium is an energy intensive process. Recycling on the other hand uses only 5% of the energy needed to smelt alumina into pure aluminium. Recycling one kilogram of aluminium saves approximately 14 kilowatts of energy. That’s the equivalent to powering a TV for 204 hours.

- Preserves landscapes. Reducing the need to extract bauxite (ore) out the ground. Recycling conserves soil integrity, wildlife habitats that are otherwise destroyed in the aluminium extraction process.

- No landfill. Valuable aluminium is diverted from landfill and stays in the loop for the manufacture of new products.

- Recycling creates jobs in the collecting and sorting of recyclables.

- Recycling conserves precious natural resources for future generations.

Extraction of aluminium

The process of making aluminium from scratch requires prodigious amounts of energy and water. Primary raw materials such as ore, bauxite and other minerals are extracted from the ground, refined and smelted into pure aluminium. This process releases high volumes of greenhouse gas emissions in the air, making it a large contributor to global warming.

At Refoil we believe it’s time the industry becomes less dependent on the extraction of aluminium. With a growing global population and a rising demand for aluminium it’s time to develop the industry in a sustainable way.

Landfill

If you disposal of aluminium sheets in the waste bin will end up in landfill. Aluminium doesn’t degrade easily. It actually takes up to 500 years before the aluminium fully disappears. So, it is always a bad idea to not recycle your aluminium sheets. Especially, because aluminium is the easiest metal to recycle.